HST Flow Controller

FLOW Controller

F : Material Flow

L : Object Location

O : Object Weight Distribution

W : Product Weight

=

+ Teach In

+ Evaluation

+ Controlling

+ Regulation

=

Being Competitive

L : Object Location

O : Object Weight Distribution

W : Product Weight

=

+ Teach In

+ Evaluation

+ Controlling

+ Regulation

=

Being Competitive

Features:

- versatile, fast, easily to operate and low cost control system

- covers many applications, also often occurring in a single production line

- control of weight, weight distribution, object position and material flow

- control of materials like cellulose, textile, paper, foils, granulate, coatings or pharmaceutical substances etc.

- on-line control of continuous and discontinuousobjects, materials and (whole) products

- application solutions thanks to a wide range of sensor versions and constructions

- teach-in functionality allows quick and automated adjustment

- digital and analog interface for external machine line control units

- software package for calibration and visualisation by/on a PC

- temporary or permanent operation with HST Analyser or HST Profiler

Description:

The HST Flow Controller is a versatile and extremely easily to handle control system, that covers a wide range of applications concerning weight, weight distribution, flow and position control. Pushing one button or applying a 24 Volts signal initiates the teach-in procedure and starts after the teach-in procedure the operation for one of the above mentioned applications.

The control application determines the type of QMS70xxx sensor, that meets the demands best. Single sided QMS70xxx sensors can be used for applications, where extremely little or thin material must be controlled and the material is in contact with the sensor or its guiding plates. The materials for this kind of control may be foils, fleeces, paper, glue coatings, granulate powder etc. One very interesting application is the control of powder or granulate flow. The HST Flow Controller can operate by evaluating the weight of continuous or discontinuous flow of powder and granulate. These both evaluation-possibilties are not restricted for material flow applications. Cellulose or textile webs represent further continuous material weight control applications. Whereas whole products aligned intermittently represent the discontinuous weight control.

Two further applications are very interesting and solve many production problems : Hereby the HST Flow Controller controls the weight distribution of whole product or discrete areas of materials. For that the teach-in procedure generates by measuring several product or discrete material areas a reference weight distribution curve. Too large deviations from this reference curve will be detected and signalised. The HST Flow Controller controls also the location and position of objects. Too large deviations will be signalised. The referring products may be ejected.

All above mentioned applications except the position control are based on QMSxxx sensors, that deliver weight quantity information. The different QMSxxx sensor versions i.e. constructions, help to find the best one for a distinct application. The HST Flow Controller is a very fast control system, which is delivered with a PC-Software for visualisation and configuration.

The HST Flow Controller can also operate either permanently or temporary with other inspection and control systems like the HST Analyser or HST Profiler to deliver more information of the production process.

The control application determines the type of QMS70xxx sensor, that meets the demands best. Single sided QMS70xxx sensors can be used for applications, where extremely little or thin material must be controlled and the material is in contact with the sensor or its guiding plates. The materials for this kind of control may be foils, fleeces, paper, glue coatings, granulate powder etc. One very interesting application is the control of powder or granulate flow. The HST Flow Controller can operate by evaluating the weight of continuous or discontinuous flow of powder and granulate. These both evaluation-possibilties are not restricted for material flow applications. Cellulose or textile webs represent further continuous material weight control applications. Whereas whole products aligned intermittently represent the discontinuous weight control.

Two further applications are very interesting and solve many production problems : Hereby the HST Flow Controller controls the weight distribution of whole product or discrete areas of materials. For that the teach-in procedure generates by measuring several product or discrete material areas a reference weight distribution curve. Too large deviations from this reference curve will be detected and signalised. The HST Flow Controller controls also the location and position of objects. Too large deviations will be signalised. The referring products may be ejected.

All above mentioned applications except the position control are based on QMSxxx sensors, that deliver weight quantity information. The different QMSxxx sensor versions i.e. constructions, help to find the best one for a distinct application. The HST Flow Controller is a very fast control system, which is delivered with a PC-Software for visualisation and configuration.

The HST Flow Controller can also operate either permanently or temporary with other inspection and control systems like the HST Analyser or HST Profiler to deliver more information of the production process.

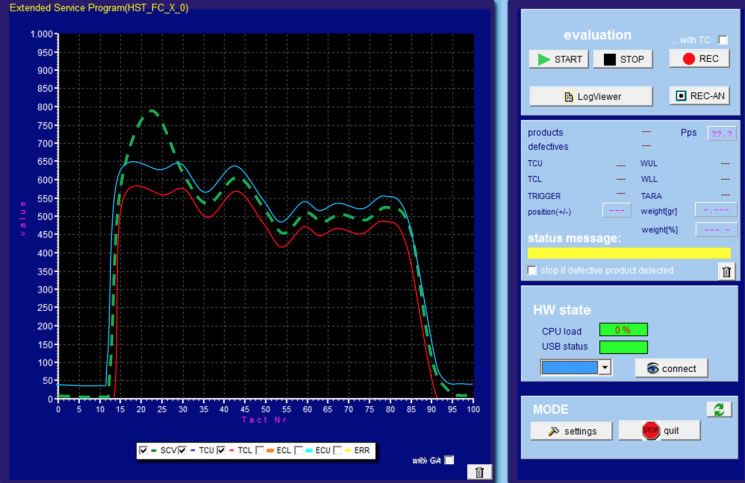

Software interface and main features

Note: The shown program interface reflects the internal settings of the HST Flow Controller. All shown elements

are used by the HST Flow Controller itself to evaluate the product parameters.

are used by the HST Flow Controller itself to evaluate the product parameters.