overview Applications

-

01: single sided sensor : permanent measurement:

- leece detection

- material quality and quantity

- label and glue detection

- foreign object detection

-

02:single sided sensor : interval measurement:

- foil detection

- mass distribution in Object (profile)

- defect detection

- object detection

-

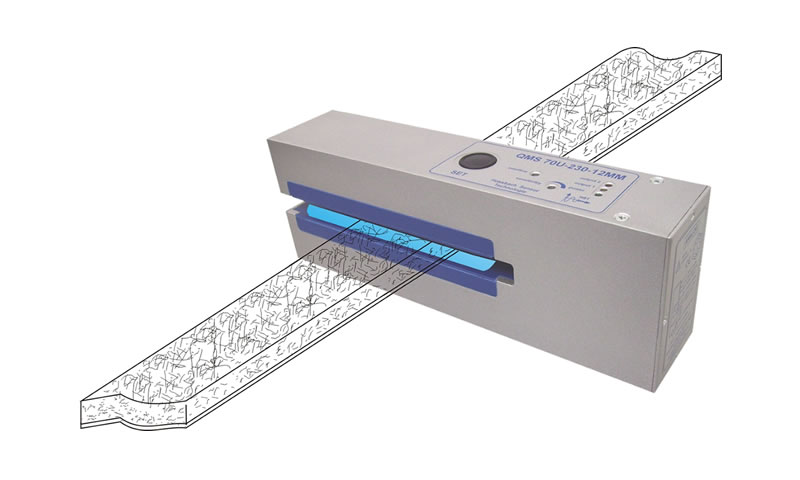

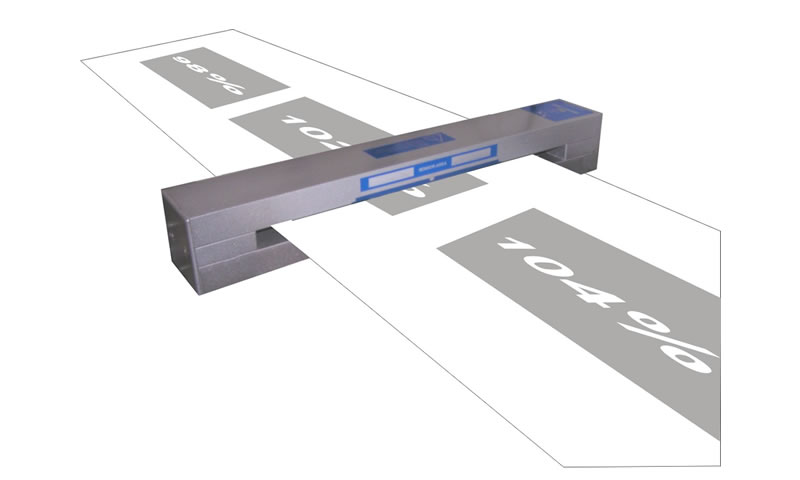

03: U-shaped sensor : permanent measurement

-

04:U-shaped sensor : interval measurement

- feminine napkin control

-

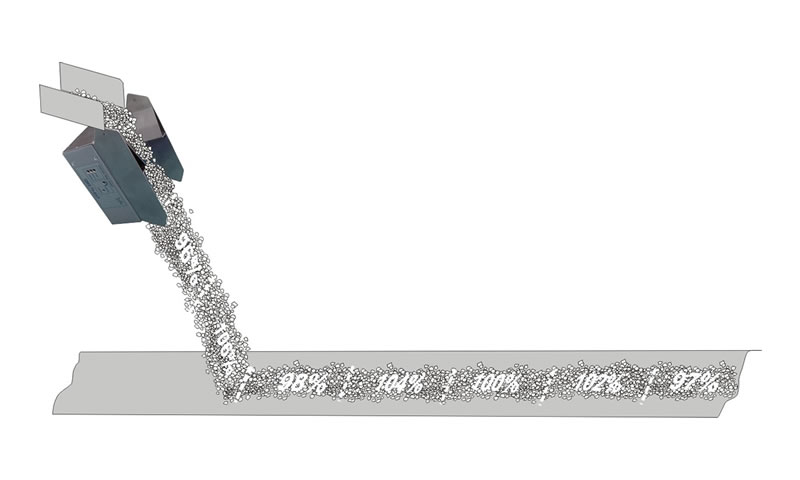

05 SAP Continuous Flow Of Material Like Granulate Or Powder

-

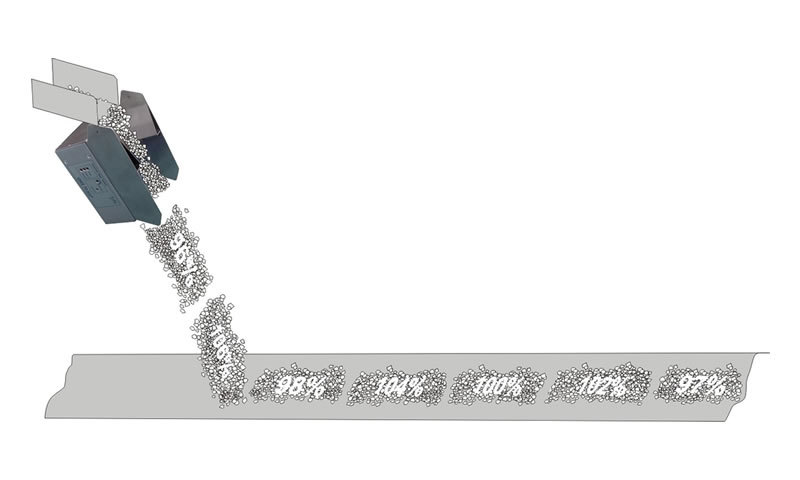

06 SAP Discrete Portions Of Material Like Granulate Or Powder

-

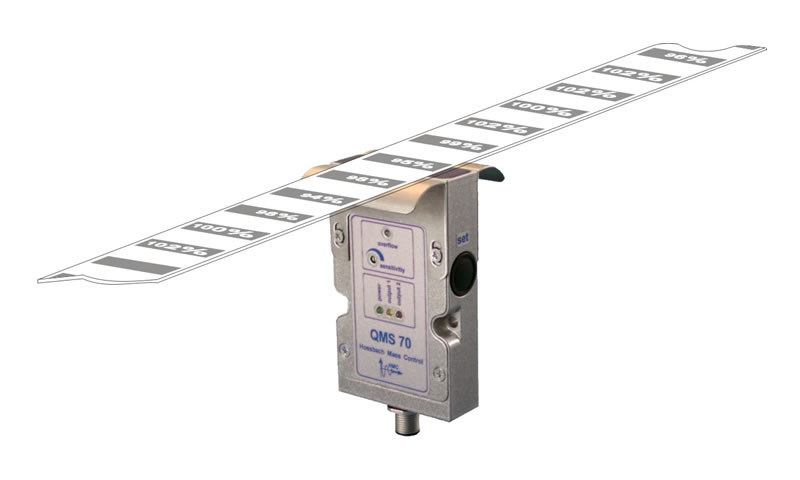

07 Glue Strip Control

- adhesive tape detection

-

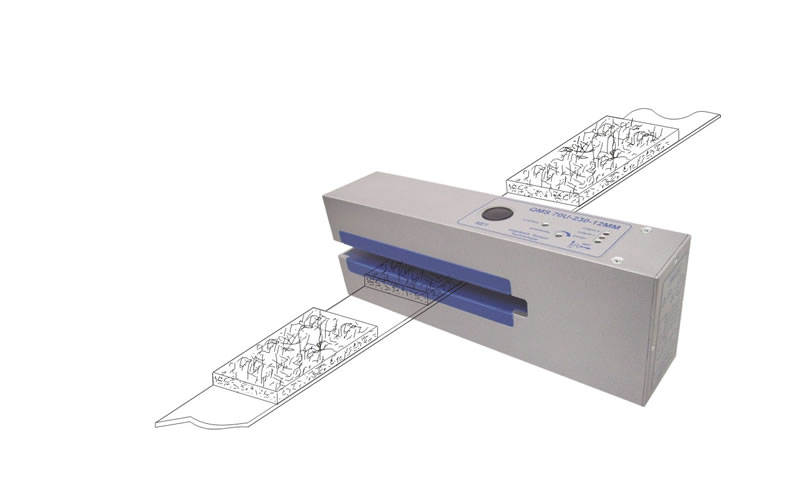

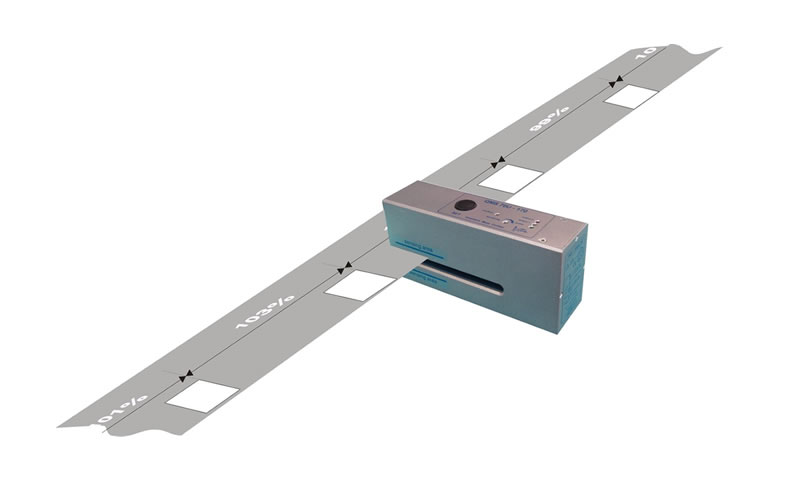

08 Position Control With Intermittently Aligned Objects

- feminine napkin control

-

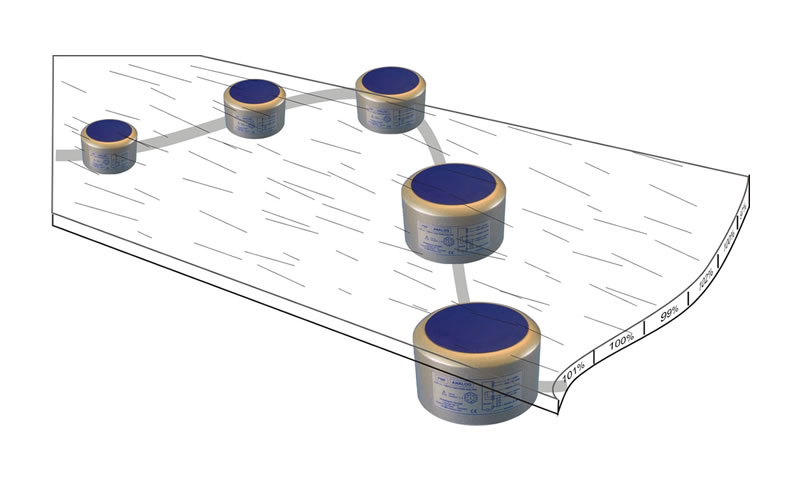

09 Weight Control Single Or Multi Layer Products

- baby diaper control

- feminine napkin control

-

10 Weight Distribution Control

Hossbach Sensor Technologie

Heinrich-Stranka-Str. 3-5

D-90765 Fuerth Germany

phone : +49-911-37677529

fax : +49-911-37677528

D-90765 Fuerth Germany

phone : +49-911-37677529

fax : +49-911-37677528